Perceived Quality 2025:

How QTRIX Transforms Car Clinics and Product Audits

Perceived Quality (PQ) has always been the crucial link between engineering and customer perception. For OEMs and Tier-1 suppliers, the PQ department essentially has two main tasks:

- 1. Knowing the benchmark – understanding exactly which products, features, and trends in the market are currently perceived as high quality.

- 2. Securing internal projects – ensuring that new products are conceived from the start so that perceived quality can be measured, tracked, and managed throughout the entire development process.

Both areas generate a flood of data, evaluations, and optimization opportunities. The challenge is to maintain transparency, set the right priorities, and make decisions based on facts.

The Trends Shaping PQ Today

In 2025, customer perception of quality is about much more than flawless panel gaps:

- Sustainability and circularity: Materials, carbon footprint, and recyclability are central quality attributes for many buyers.

- Software quality and HMI: Stability, usability, and update capability impact perceptions of premium quality just as much as physical craftsmanship.

- Everyday usability & TCO: Charging speed, serviceability, and resale value are decisive factors for customers.

- Multisensory experience: Touch, acoustics, smell, and lighting shape first impressions – and thus influence purchasing decisions.

For PQ departments, this means: benchmark analysis must be broader, deeper, and faster. At the same time, internal projects require transparent processes that can reflect and track these demands.

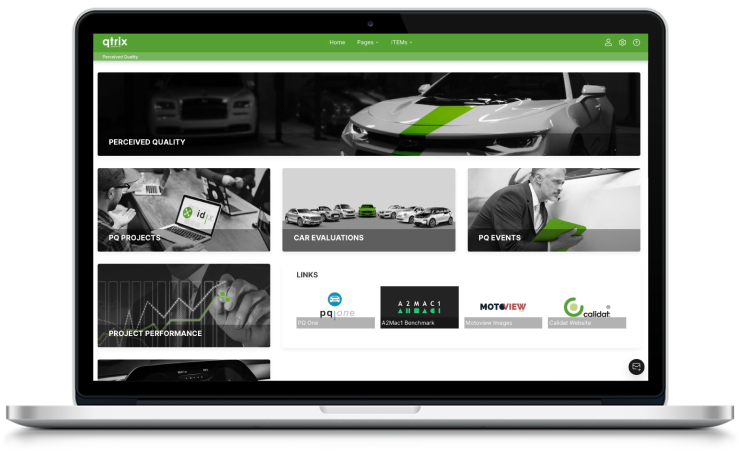

QTRIX as a PQ 4.0 Enabler

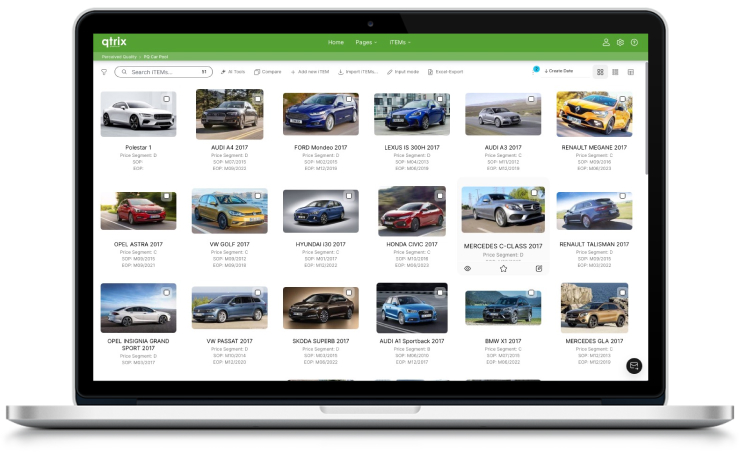

This is where QTRIX comes in: a platform that integrates Car Clinics, Product Audits, and project steering into one global solution.

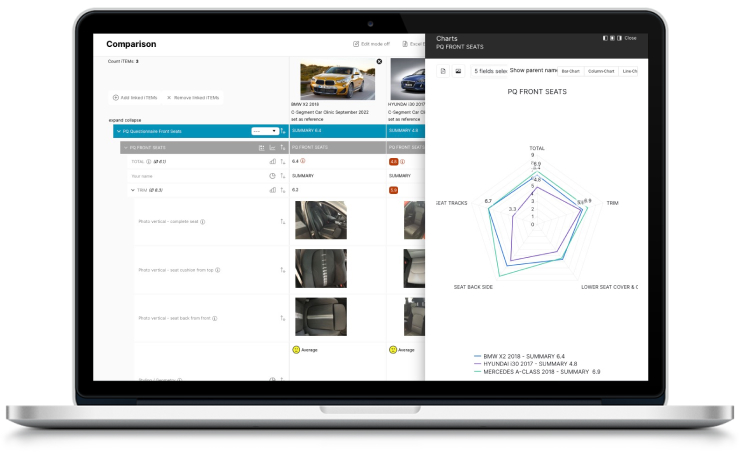

1. Understanding the benchmark

- All market data, Car Clinic, and audit results are centrally available.

- Global teams access the same shared database – while detailed role-based access rights ensure everyone only sees what they are supposed to.

2. Steering internal projects

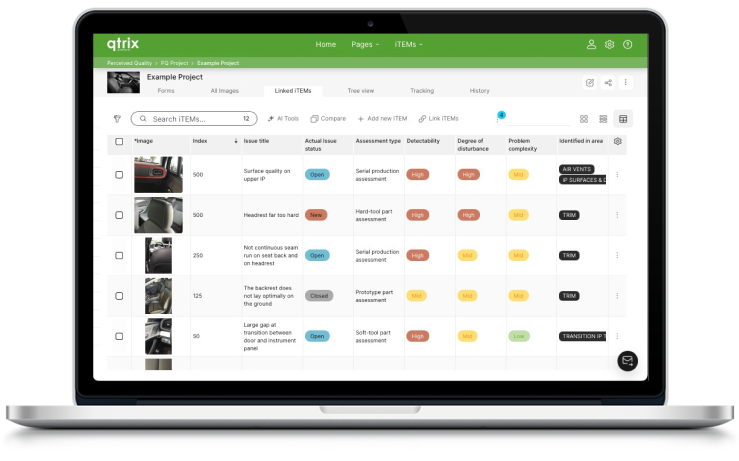

- PQ Issue Tracking: Issues identified during audits are logged, tracked, and assigned directly within the system.

- Automated workflow management: Tasks are created and automatically forwarded via email to the responsible colleague. Automatic reminders notify teams when due dates are missed.

- Prioritization & transparency: Dashboards highlight which measures carry the highest priority.

- Target Scores: PQ goals can be monitored from concept phase through to the final product – including visualizations of target vs. actual scores.

- Global overview: All issues can be viewed in one table or filtered by project, with full history, responsibilities, and status tracking.

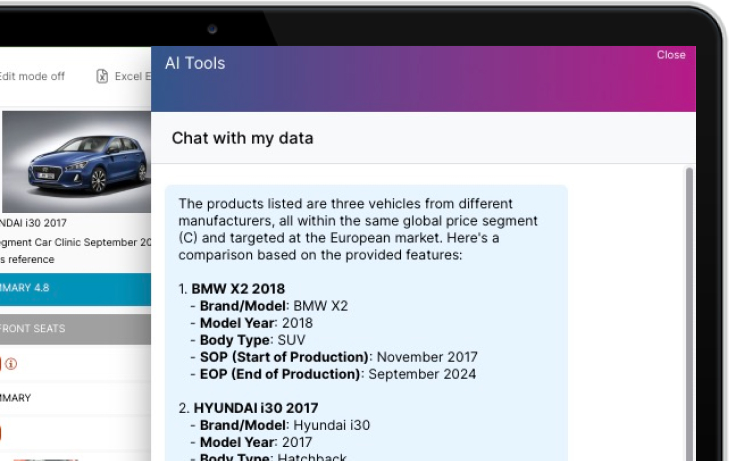

3. Intelligent support with AI

- An integrated AI chatbot helps analyze data, uncovers hidden patterns, and provides insights that raw results alone would not reveal.

- Teams can focus their energy on optimization instead of wasting time searching or cleaning data.

Digital data capture instead of paper – participants document directly via tablet or mobile phone, including photos, videos, and voice input.

Granular data collection– highlights and issues are recorded immediately, then automatically classified (PQ attributes, components, interior zones).

AI-powered analysis– patterns and correlations become visible, deviations instantly detectable.

Knowledge management– all data flows into a central database with full-text search, filters, and a lessons-learned function.

Lifecycle networking– integration of Car Clinics, product audits, and series customer feedback.

PQ issue tracking & workflow management – issues identified during audits can be tracked seamlessly in the system. Tasks can be created directly and automatically sent by email to responsible colleagues. Individual process phases and roles can be defined flexibly. All open and closed PQ issues are visible at a glance, reports can be generated automatically and exported as PowerPoint – perfect for project reviews or management presentations.

Practical Example

Imagine a vehicle audit documents 50 PQ issues. Traditionally, these would have been collected in Excel sheets, with unclear responsibilities and a high risk of mis-prioritization.

With QTRIX:

- Each issue is recorded in the system, assigned automatically to a responsible person, and given a due date.

- All issues are integrated into the global database, visible to every relevant team.

- Dashboards highlight which issues have the biggest impact on the Final Product Score.

- Automatic reminders are triggered if deadlines are missed.

- At any moment, a project manager can generate a PPT export with the current status – ready for reviews or management meetings.

Conclusion

Perceived Quality 4.0 is no longer just about collecting customer feedback – it’s about globally steering knowledge and making it actionable in development projects.

With QTRIX:

- Car Clinics and benchmark analyses become faster, more transparent, and globally accessible.

- Internal projects can be monitored from the start with measurable Target Scores.

- PQ issues no longer disappear into spreadsheets but are tracked seamlessly until resolution.

- AI-driven insights help identify trends early and guide decisions in the right direction.

This makes QTRIX the foundation for PQ departments worldwide to work more efficiently – and it frees teams to focus on what really matters: optimizing and continuously improving the perceived quality of products.