Perceived Quality 2025:

Wie QTRIX Car Clinics und Produktaudits transformiert

Perceived Quality (PQ) war schon immer das entscheidende Bindeglied zwischen Engineering und Kundenwahrnehmung. Für OEMs und Tier-1-Lieferanten hat der PQ-Bereich im Wesentlichen zwei Hauptaufgaben:

- 1. Den Benchmark kennen – genau zu verstehen, welche Produkte, Features und Trends im Markt derzeit als qualitativ hochwertig wahrgenommen werden.

- 2. Interne Projekte absichern – sicherzustellen, dass neue Produkte von Beginn an so konzipiert werden, dass die wahrgenommene Qualität über den gesamten Entwicklungsprozess hinweg messbar, nachverfolgbar und steuerbar ist.

In beiden Bereichen entstehen große Mengen an Daten, Bewertungen und Optimierungspotenzialen. Entscheidend ist es, Transparenz zu schaffen, Prioritäten richtig zu setzen und Entscheidungen auf Basis belastbarer Fakten zu treffen.

Trends, die Perceived Quality heute prägen

Im Jahr 2025 geht es bei der wahrgenommenen Qualität aus Kundensicht um weit mehr als makellose Spaltmaße:

- Nachhaltigkeit und Zirkularität Materialien, CO₂-Bilanz und Recyclingfähigkeit sind für viele Käufer zentrale Qualitätsmerkmale.

- Softwarequalität und HMI: Stabilität, Benutzerfreundlichkeit und Updatefähigkeit beeinflussen die Wahrnehmung von Premiumqualität in gleichem Maße wie handwerkliche Verarbeitungsqualität.

- Alltagstauglichkeit & TCO: Ladegeschwindigkeit, Servicefreundlichkeit und Wiederverkaufswert sind für Kundinnen und Kunden entscheidende Faktoren.

- Multisensorische Erfahrung: Haptik, Akustik, Geruch und Licht prägen den ersten Eindruck – und beeinflussen damit Kaufentscheidungen.

Für PQ-Abteilungen bedeutet das: Benchmark-Analysen müssen breiter, tiefer und schneller werden. Gleichzeitig erfordern interne Projekte transparente Prozesse, die diese Anforderungen abbilden und nachvollziehbar machen.

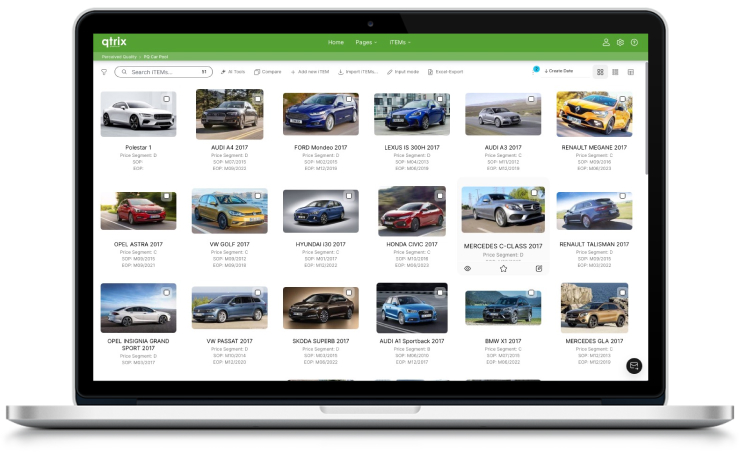

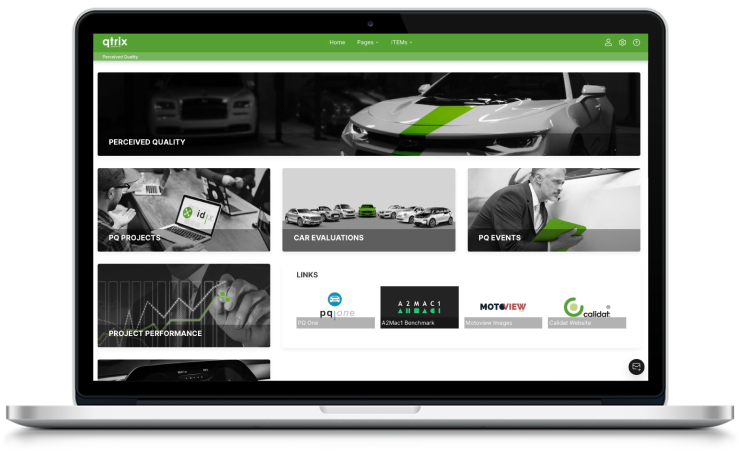

QTRIX als PQ-4.0-Enabler

Genau hier setzt QTRIX an: eine Plattform, die Car Clinics, Produktaudits und Projektsteuerung in einer globalen Lösung vereint.

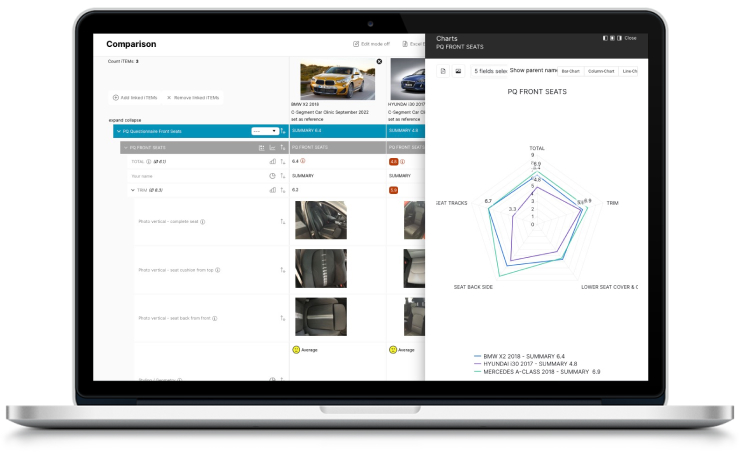

1. Den Benchmark verstehen

- Alle Marktdaten sowie Car-Clinic- und Audit-Ergebnisse sind zentral verfügbar.

- Globale Teams greifen auf dieselbe zentrale Datenbasis zu – während fein abgestufte, rollenbasierte Zugriffsrechte sicherstellen, dass jede Person nur das sieht, wofür sie berechtigt ist.

2. Interne Projekte steuern

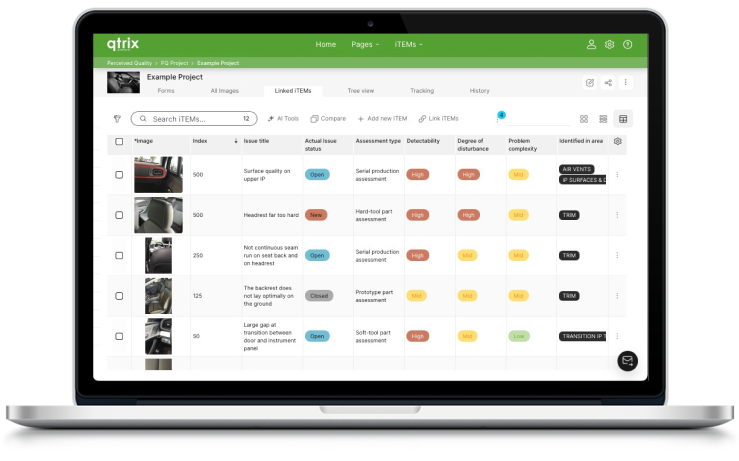

- Tracking von PQ-Issues Im Rahmen von Audits identifizierte Issues werden direkt im System erfasst, nachverfolgt und zugewiesen.

- Automatisiertes Workflow-Management Aufgaben werden erstellt und automatisch per E-Mail an die verantwortlichen Kolleginnen und Kollegen weitergeleitet. Automatische Erinnerungen informieren Teams, wenn Fristen überschritten werden.

- Priorisierung und Transparenz: Dashboards zeigen auf einen Blick, welche Maßnahmen priorisiert werden müssen.

- Target Scores: PQ-Ziele können über den gesamten Entwicklungsprozess hinweg überwacht werden – von der Konzeptphase bis zum finalen Produkt, einschließlich transparenter Soll-/Ist-Visualisierungen.

- Zentraler globaler Überblick Alle Issues lassen sich in einer zentralen Übersicht darstellen oder projektbezogen filtern – inklusive vollständiger Historie, klarer Verantwortlichkeiten und transparentem Status-Tracking.

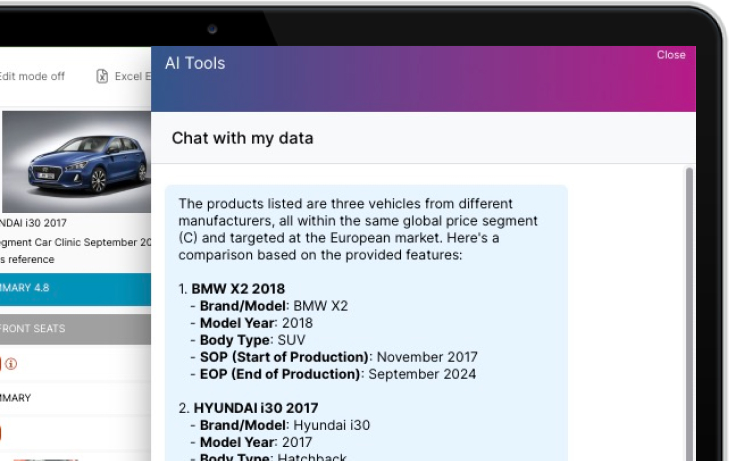

3. Intelligente Unterstützung durch KI

- Ein integrierter KI-Chatbot unterstützt bei der Analyse der Daten, deckt verborgene Muster auf und liefert Erkenntnisse, die aus reinen Rohdaten allein nicht ersichtlich wären.

- So können sich Teams auf Optimierung fokussieren – statt Zeit für Datensuche und -bereinigung aufzuwenden.

Digitale Erfassung statt Papier – Probanden dokumentieren direkt per Tablet oder Mobiltelefon inkl. Fotos, Videos, Sprache.

Granulare Datenaufnahme– Highlights und Issues werden unmittelbar erfasst, anschließend automatisch klassifiziert (PQ-Attribute, Bauteile, Interieur-Zonen).

KI-gestützte Analyse– Muster und Korrelationen werden sichtbar, Abweichungen sofort erkennbar.

Wissensmanagement– Alle Daten fließen in eine zentrale Datenbank mit Volltextsuche, Filter und Lessons Learned-Funktion.

Vernetzung im Lebenszyklus– Integration von Car Clinics, Produktaudits und Kundenfeedback in Serie.

PQ-Issue-Tracking & Workflow-Management – während der Audits erkannte Issues können im System lückenlos nachverfolgt werden. Aufgaben lassen sich direkt erstellen und automatisiert per Mail an die zuständigen Kollegen weiterleiten. Individuelle Prozessphasen und Rollen können flexibel definiert werden. Alle offenen und abgeschlossenen PQ-Issues sind auf einen Blick sichtbar, Berichte lassen sich automatisiert generieren und als PPT exportieren – perfekt für Projekt-Reviews oder Management-Präsentationen.

Beispiel aus der Praxis

Stellen Sie sich vor, ein Fahrzeugaudit dokumentiert 50 PQ-Issues. Traditionell wären diese in Excel-Listen gesammelt worden – mit unklaren Verantwortlichkeiten und einem hohen Risiko falscher Priorisierung.

Mit QTRIX:

- Jedes Issue wird im System erfasst, automatisch einer verantwortlichen Person zugewiesen und mit einer Frist versehen.

- Alle Issues werden in die globale Datenbank integriert und sind für alle relevanten Teams sichtbar.

- Dashboards machen sichtbar, welche Issues den größten Einfluss auf den Final Product Score. haben.

- Werden Fristen überschritten, greifen automatische Erinnerungen.

- Projektverantwortliche können jederzeit einen PPT export mit dem aktuellen Status erstellen – direkt einsetzbar für Reviews oder Management-Meetings.

Fazit

Perceived Quality 4.0 bedeutet längst mehr als das Sammeln von Kundenfeedback – es geht darum, Wissen global zu steuern und in Entwicklungsprojekten wirksam umzusetzen.

Mit QTRIX:

- Car Clinics und Benchmark-Analysen werden schneller, transparenter und weltweit zugänglich.

- Interne Projekte werden von Anfang an über messbare Target Scores gesteuert.

- PQ-Issues verschwinden nicht länger in Tabellen, sondern werden nahtlos bis zur Lösung nachverfolgt.

- KI-gestützte Insights helfen dabei, Trends frühzeitig zu erkennen und Entscheidungen gezielt in die richtige Richtung zu lenken.

Damit wird QTRIX zur Grundlage für PQ-Abteilungen weltweit, effizienter zu arbeiten – und schafft Freiraum für das, was wirklich zählt: die Optimierung und kontinuierliche Verbesserung der wahrgenommenen Produktqualität.